“Hocreboard” Calcium silicate board use to wall and ceiling

1. Durability;

2. High density and light weight;

3. Fireproof, waterproof

(High Temperature 650° and 1000°C calcium silicate boards for industrial furnaces, please click link at: http://www.hocre-board.com/products/high-temperature-calcium-silicate-insulation-board)

Product Description

We are supplying good quality calcium silicate boards (100% asbestos, meerschaum and Brucite free), and non-asbestos fiber reinforced calcium silicate boards.

Calcium Silicate Board Specifications:

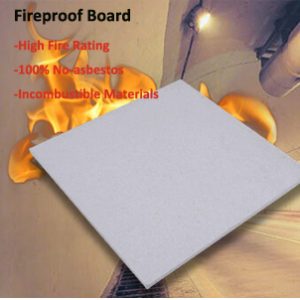

100% Non Asbestos Fireproof Calcium Silicate Board

-Content of chloride ion:0%

-Water Content: <10%

-Water aborsption:<40%

-Percentage of water swelling:≤0.25%

-Water vapour permeability:No water vapour after 24hours’ test

-Thermal conductivity:≤0.20 W/mk

-Thermal shrinkage:≤0.5%

-Fire Resistance:Incombustibility A1 Class(GB8624-2006)

-Fire Resistance limit:≥240minutes

-Bending Strength:≥10Mpa

-Impact strength:≥5.0KJ/m2

-Screw-withdrawal force:≥60N/mm

-Freezing resistance:No cracking and layering after 25 times of freeze thawing test

-Sound Insulation:>46db

-Radioactivity:<1.0lRa,<1.0lr

-Asbestos:Asbestos free

-Formaldehyde release:No formaldehyde

Calcium Silicate Board characteristics:

1) Non toxic

2) Fireproof

3) Soundproof

4) Sawable

5) Thermal insulation

6) Impact resistant

7) Planeable

8)Mothproof

9) Moisture proof

Calcium Silicate Board Application:

-3.5-6mm for interior ceiling and can be used for the facing panel of Sandwich Board

-8-15mm for the interior partition

-8-12mm for the External Siding, Cladding or Facade

-18-30mm for Indoor Floor Decking

-9mm-24mm for ventilation,smoke extract & kitchen Exhaust Duct

Installation

Tools:

No special tools are required. The products can be used with normal nails, fastened by normal or self-drilling screws and cut by an electric power saw with a diamond blade.

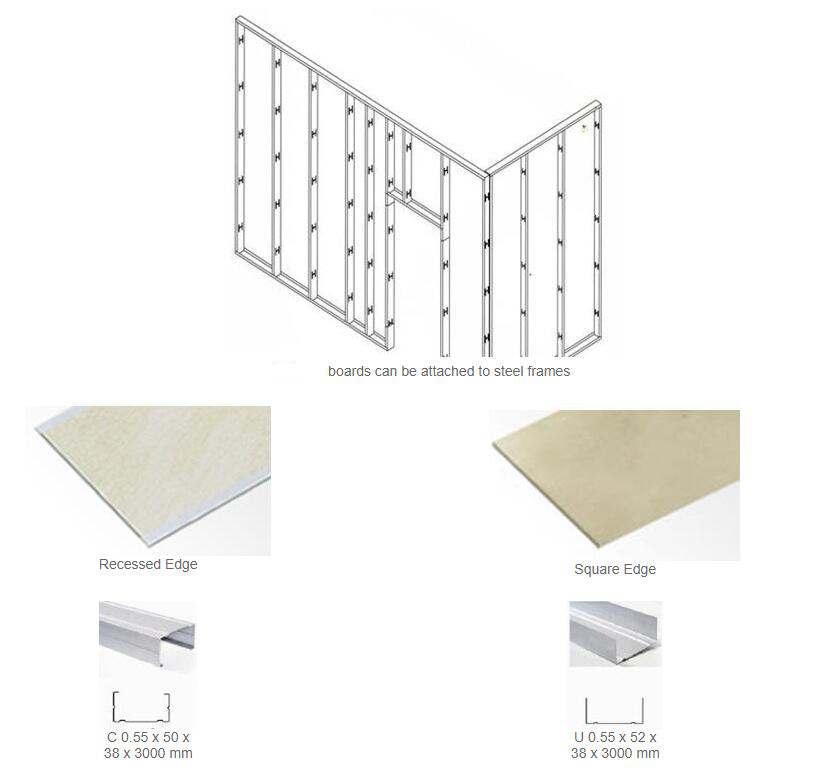

Fixing:

Calcium Silicate board can be fixed to both timber (minimum size 1.5 x 3 inches) or steel frames (at least 0.55 mm thickness). The board must be supported at the edge at intermediate positions with centers not exceeding 600 mm. Screws must be located more than 12 mm from edges and 50 mm from board corners.

Fastener:

Fasteners can be both nails and screws. It can be nailed directly to timber supports with round wire nails. For metal screws, the size and length of the screw depends on the thickness of the board and the gauge of framing. Pre-drilling the board is a must unless self-embedding, self-drilling head screws.

Jointing:

Since calcium silicate board is subject to slight dimensional changes, a butt joint can be used in dry partitioning areas or where an exposed joint appearance is acceptable. For better water protection, either flexible acrylic or polyurethane based sealant can be used to seal gaps of 3-5mm.

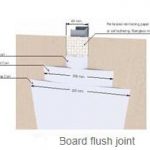

Flush Joint for Board, Recessed Edge

First coat: Fill the recessed area to the face of the sheet by using a jointing compound then embed the fibreglass mesh tape into the joint.

Second coat: Apply second coat at 200 mm width. Allow it to dry thoroughly before applying a finishing coat.

Finishing coat: Apply third coat at 300 mm width. Allow it to dry completely before sanding.

Recommended Frame Specification – For Internal Partition

Galvanized steel frame No.24 (0.55 BMT) is recommended to be used as stud for internal partition using Fiber cement board. Stud shall be fixed at the spacing of 600 x 2.400 mm. Details of ideal stud size are shown as follows.

Package&Loading:

Project Case:

******************************************************************************************************************************

Related Products: