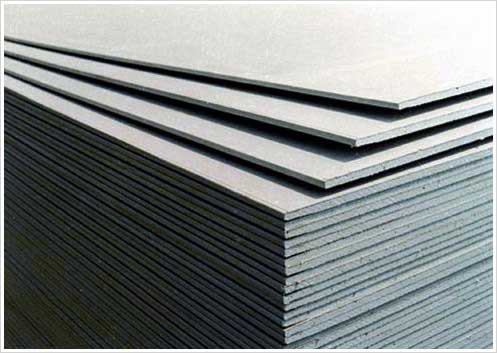

“Hocreboard” Fiber cement board

Raw Materials:Cement,Quartz Sand,Fiber and Other non hazardous ingredients

Basic Color:Grey

Density:≥1.10g/cm3

Moisture Content:≤10%

Water Absorbing Capacity:≤35%

Thermal Conductivity:Average≤0.20W/MK

Bending Strength:Transverse≥11.0N/mm3 Vertical≥8.5N/mm3

Radioactivity:Conforming to GB6566-2001 A Class

Fire Resistance:Incombustibility A Class(GB8624-A)

Size: 1220×2440,1200×2400, 600×1200, 600×600,595×595…

Max Length:3050mm

Thickness: 3.5mm-25mm

Edge: Square-cut edge/Recessed edge/Tapered edge/Bevel edge

Fiber Cement Board has 3 kinds of Density:

-Low Density: 1.1-1.3g/cm3

-Middle Density: 1.3-1.4g/cm3

-High Density: 1.4-1.6g/cm3

Fire resistant:

It is Flame Resistant to Combustion at 800 and Remains Flameless at 1200 .

Non-Flammability: Grade A

Weather resistant:

Resistant to Deformation in Wet, Hot and Dry Conditions.

Can be used at -40 degree.Out of Shape Rate in the Condition of Wet or Dry is 0.26%.

Water and Damp Proof:

The board still keeps Intact after being Soaked in Water for One Month ,the Phenomenon of Swelling and Out of Shape will Not Happen.

It will NOT Disintegrate when Immersed in Water Or Exposed to Freeze/Thaw Cycles for Prolonged Periods of Time.

Bug & Mildew free:

After tests under ASTM G-21, this board has been found to be Non-Nutrient to Mold ,Fungus Growth or Insect Life.

Insulation:

After Inspection by the National Center for Quality Supervision and Testing of Fire Building Materials (NFTC) it has been found that the Superior Sound Insulation Factor of a Wall built from the board ranges between 44dB and 47 dB

In addition to being a great Sound insulator ,This board benefits from having a Low Thermal Conductivity of 0.216 W/Mk which makes it a superior Heat Insulator.

Environmentally Friendly:

This Environmentally Friendly board is manufactured from a unique blend of Mineral Components, and does NOT contain any Toxic ingredients ,Asbestos Formaldehyde or Ammonia.

Production Flow:

Fiber Cement Board Application:

-3.5-6mm for interior ceiling and can be used for the facing panel of Sandwich Board

-8-15mm for the interior partition

-8-12mm for the External Siding, Cladding or Facade

-18-22mm for the furniture desk

-18-30mm for Indoor Floor Decking

-22-30mm for Indoor Stair

Installation

Tools:

No special tools are required. The products can be used with normal nails, fastened by normal or self-drilling screws and cut by an electric power saw with a diamond blade.

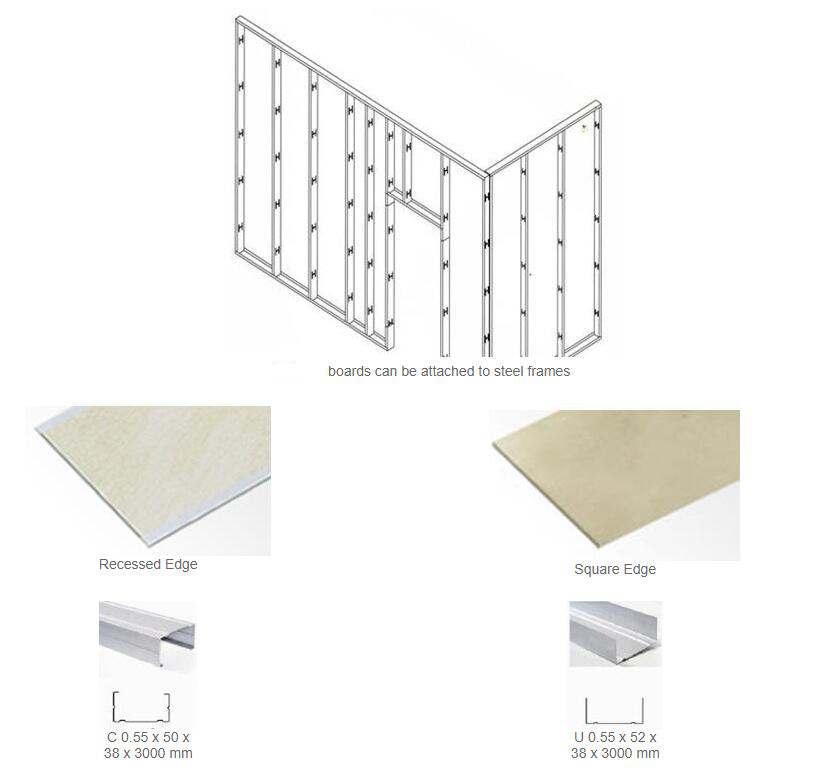

Fixing:

Fiber cement board can be fixed to both timber (minimum size 1.5 x 3 inches) or steel frames (at least 0.55 mm thickness). The board must be supported at the edge at intermediate positions with centers not exceeding 600 mm. Screws must be located more than 12 mm from edges and 50 mm from board corners.

Fastener:

Fasteners can be both nails and screws. It can be nailed directly to timber supports with round wire nails. For metal screws, the size and length of the screw depends on the thickness of the board and the gauge of framing. Pre-drilling the board is a must unless self-embedding, self-drilling head screws.< strong>Jointing:

Since fibre-cement board is subject to slight dimensional changes, a butt joint can be used in dry partitioning areas or where an exposed joint appearance is acceptable. For better water protection, either flexible acrylic or polyurethane based sealant can be used to seal gaps of 3-5mm.

Flush Joint for Board, Recessed Edge

First coat: Fill the recessed area to the face of the sheet by using a jointing compound then embed the fibreglass mesh tape into the joint.

Second coat: Apply second coat at 200 mm width. Allow it to dry thoroughly before applying a finishing coat.

Finishing coat: Apply third coat at 300 mm width. Allow it to dry completely before sanding.

Recommended Frame Specification – For Internal Partition

Galvanized steel frame No.24 (0.55 BMT) is recommended to be used as stud for internal partition using Fiber cement board. Stud shall be fixed at the spacing of 600 x 2.400 mm. Details of ideal stud size are shown as follows.

We can make the colored fiber cement board according to client’s needs.

Package&Loading:

Project Case:

For Cement Board Siding, please visit at http://www.hocre-board.com/products/fiber-cement-plank-board

*************************************

Related Products: